High Parameter Waste Heat Boiler Technology

|

Technology Introduction

|

|

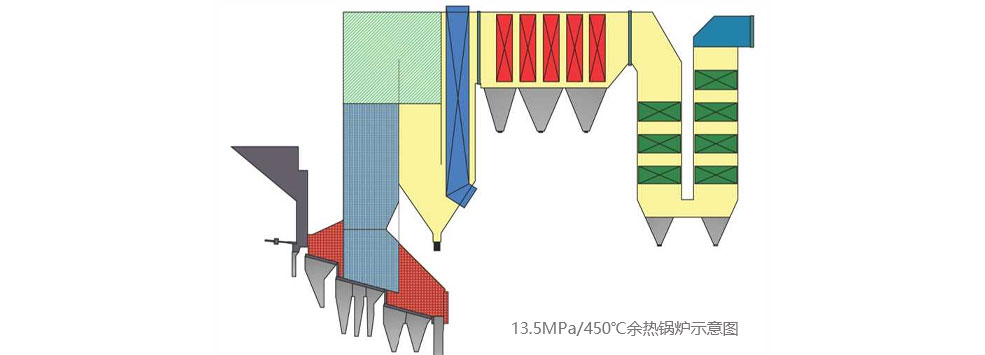

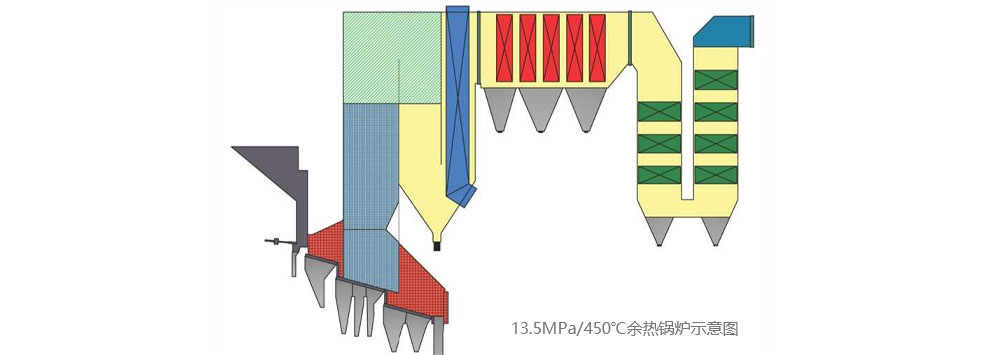

Introduction to High Parameter Waste Heat Boiler Technology: High-parameter waste heat boiler technology refers to the scientific and gradual elevation of the main steam parameters of the boiler. The advancement entails gradually increasing the main steam parameter of the waste heat boiler from medium-temperature medium-pressure parameter (4.0 MPa, 400 ℃) to medium-temperature sub-high-pressure parameter (6.4 MPa, 450 ℃), sub-high-temperature sub-high pressure parameters (6.4 MPa, 485 ℃), medium-temperature ultra-high-pressure parameter (13.5 MPa, 450 ℃), and sub-high-temperature ultra-high-pressure parameter (13.5 MPa, 485 ℃). |

Highlights

|

Plant-wide thermal efficiency improvement to enhance economic efficiency

|

|

Optimizing high-temperature anti-corrosion solutions for project stability

|

|

Refined anticorrosion processes Tailored anti-corrosion processes for high-risk areas

|

|

Optimized heating surface arrangement for enhanced efficiency, minimize the risk of ash accumulation, and enhance the dynamics of the water cycle

|

|

Enhancing superheater material for superior corrosion resistance of the material

|

|

Precision thermal calculation and optimal heating surfaces arrangement

|

|

Comprehensive CFD numerical modeling for waste heat boiler flow field optimization

|

|

|

Technical Applications

(Part of the high parameter boiler performance of SUS Environment)

|

No. |

Project Name |

Processing scale(t/d) |

Main Steam Parameters(MPa,℃) |

|

1 |

Sanhe Project |

2×1000 |

13.5,450 |

|

2 |

Nanchang Project |

3×880 |

6.4,485 |

|

3 |

Hangzhou Project |

6×870 |

5.3,450 |

|

4 |

Qingdao Project |

3×825 |

6.4,485 |

|

5 |

Jiaxing Project |

3×825 |

5.3,485 |

|

6 |

Taiyuan Project |

4×750 |

6.4,485 |

|

7 |

Huangdao Project |

3×750 |

6.4,485 |

|

8 |

Gaoling Project |

3×750 |

6.4,485 |

|

9 |

Liuzhou Project |

3×750 |

6.4,450 |

|

10 |

Nanning Project |

3×750 |

6.4,450 |

|

11 |

Xianghe Project |

1×750 |

6.4,450 |

|

12 |

Shangcai Project |

1×700 |

6.4,450 |

|

13 |

Xinhui Project |

2×750 |

13.5,485 |

|

Technology Introduction

|

|

Introduction to High Parameter Waste Heat Boiler Technology: High-parameter waste heat boiler technology refers to the scientific and gradual elevation of the main steam parameters of the boiler. The advancement entails gradually increasing the main steam parameter of the waste heat boiler from medium-temperature medium-pressure parameter (4.0 MPa, 400 ℃) to medium-temperature sub-high-pressure parameter (6.4 MPa, 450 ℃), sub-high-temperature sub-high pressure parameters (6.4 MPa, 485 ℃), medium-temperature ultra-high-pressure parameter (13.5 MPa, 450 ℃), and sub-high-temperature ultra-high-pressure parameter (13.5 MPa, 485 ℃). |

Highlights

|

Plant-wide thermal efficiency improvement to enhance economic efficiency

|

|

Optimizing high-temperature anti-corrosion solutions for project stability

|

|

Refined anticorrosion processes Tailored anti-corrosion processes for high-risk areas

|

|

Optimized heating surface arrangement for enhanced efficiency, minimize the risk of ash accumulation, and enhance the dynamics of the water cycle

|

|

Enhancing superheater material for superior corrosion resistance of the material

|

|

Precision thermal calculation and optimal heating surfaces arrangement

|

|

Comprehensive CFD numerical modeling for waste heat boiler flow field optimization

|

|

|

Technical Applications

(Part of the high parameter boiler performance of SUS Environment)

|

No. |

Project Name |

Processing scale(t/d) |

Main Steam Parameters(MPa,℃) |

|

1 |

Sanhe Project |

2×1000 |

13.5,450 |

|

2 |

Nanchang Project |

3×880 |

6.4,485 |

|

3 |

Hangzhou Project |

6×870 |

5.3,450 |

|

4 |

Qingdao Project |

3×825 |

6.4,485 |

|

5 |

Jiaxing Project |

3×825 |

5.3,485 |

|

6 |

Taiyuan Project |

4×750 |

6.4,485 |

|

7 |

Huangdao Project |

3×750 |

6.4,485 |

|

8 |

Gaoling Project |

3×750 |

6.4,485 |

|

9 |

Liuzhou Project |

3×750 |

6.4,450 |

|

10 |

Nanning Project |

3×750 |

6.4,450 |

|

11 |

Xianghe Project

|

1×750 |

6.4,450 |

|

12 |

Shangcai Project

|

1×700 |

6.4,450 |

|

13 |

Xinhui project |

2×750 |

13.5,485 |