Mechanical Grate Furnace Technology

|

Technology Introduction

|

|

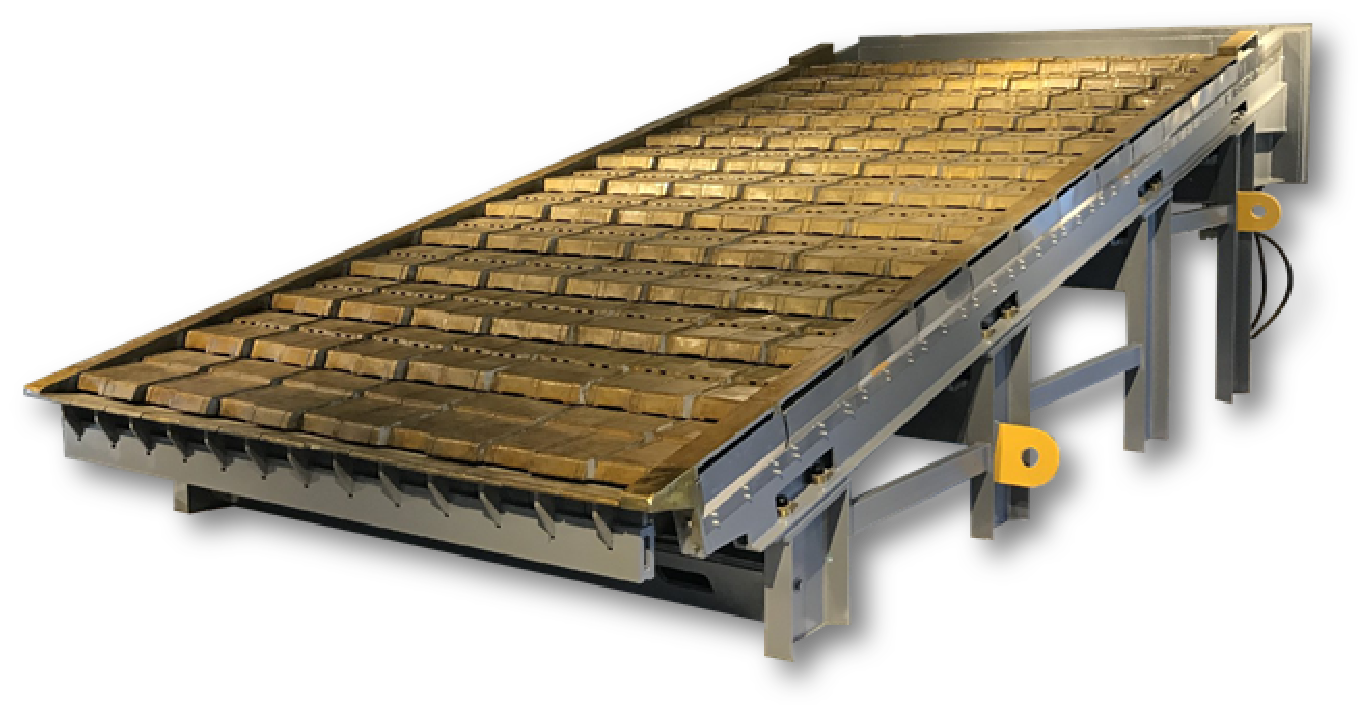

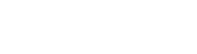

Introduction to Mechanical Grate Furnace Technology: Mechanical grate furnace technology stands as the cornerstone of waste-to-energy projects. In line with waste characteristics, SUS has comprehensively enhanced the "Von-Roll-Hitachi Zosen Mechanical Grate Furnace" technology, resulting in a complete range of solutions adapted to the waste with varying calorific values and incinerator sizes. SUS has the independent R&D and manufacturing base for mechanical grate furnace technology. |

Highlights

|

Modularization Our grate embraces a modular design to enhance precision. This approach not only ensures accuracy but also effectively minimizes installation time, streamlining project timelines for optimal efficiency. |

|

High overload capacity Ample grate area Low design mechanical load Excellent grate overload capacity

|

|

Low operating and maintenance costs Mature grate technology Stable and reliable operation Low failure rae

|

|

Highly adaptable The incinerator technology is continuously optimized to suit the unique characteristics of waste with its adaptability to various kinds of waste found across all regions of China. Good adaptability

|

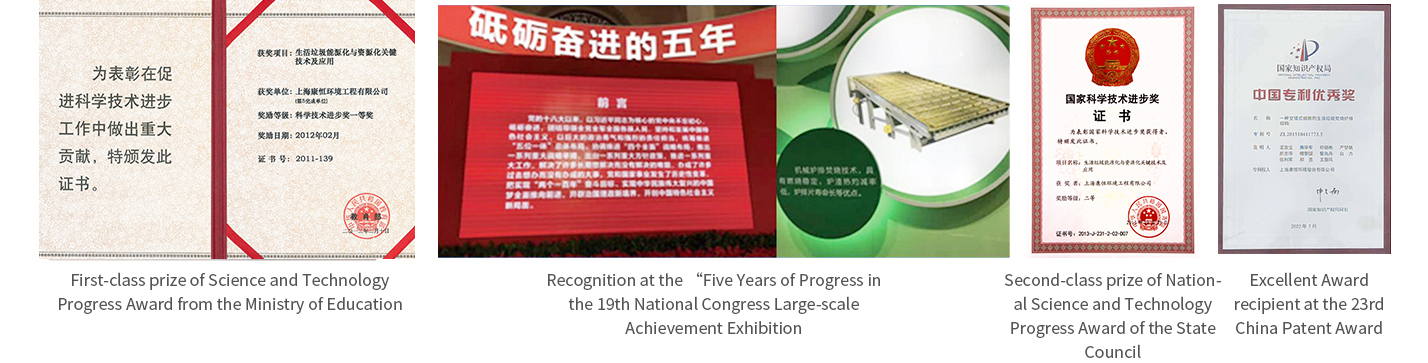

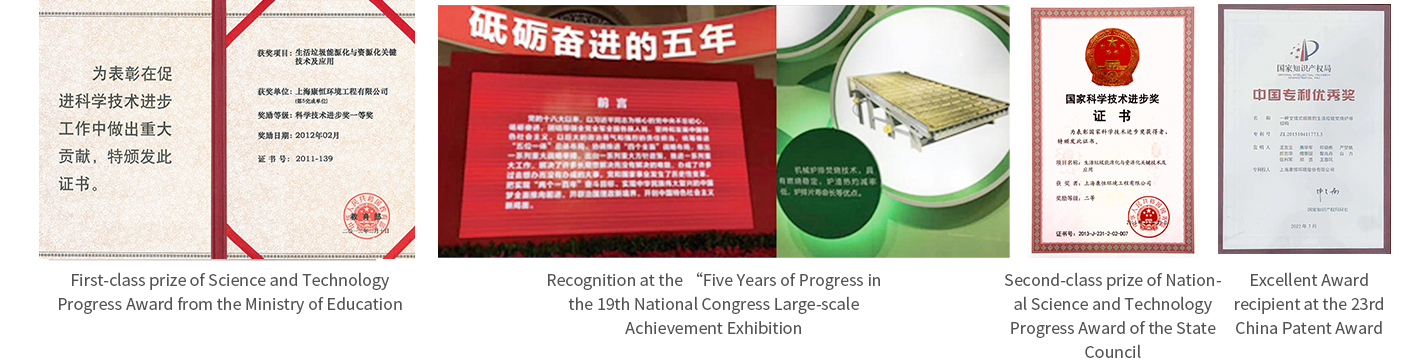

Technical Honors

Technical Applications

As of June 2023, SUS has supplied equipment to 261 waste-to-energy plants and 496 incineration lines across China. These installations boast a total waste treatment capacity exceeding 280,000 tons/day (excluding Hitachi).

In May 2021, SUS achieved a significant milestone with the operation of the first domestic 1,000-ton mechanical grate furnace at the Beijing Yanjiao Project (Sanhe Project). This groundbreaking technology not only reduces unit investment and operational cost but also delivers high combustion efficiency, high thermal stability, and a low ash thermal scorch reduction rate.

|

Technology Introduction

|

|

Introduction to Mechanical Grate Furnace Technology: Mechanical grate furnace technology stands as the cornerstone of waste-to-energy projects. In line with waste characteristics, SUS has comprehensively enhanced the "Von-Roll-Hitachi Zosen Mechanical Grate Furnace" technology, resulting in a complete range of solutions adapted to the waste with varying calorific values and incinerator sizes. SUS has the independent R&D and manufacturing base for mechanical grate furnace technology. |

Highlights

|

Modularization Our grate embraces a modular design to enhance precision. This approach not only ensures accuracy but also effectively minimizes installation time, streamlining project timelines for optimal efficiency.

|

|

High overload capacity Ample grate area Low design mechanical load Excellent grate overload capacity

|

|

Low operating and maintenance costs Mature grate technology Stable and reliable operation Low failure rate

|

|

Highly adaptable The incinerator technology is continuously optimized to suit the unique characteristics of waste with its adaptability to various kinds of waste found across all regions of China. Good adaptability

|

Technical Honors

Technical Applications

As of June 2023, SUS has supplied equipment to 261 waste-to-energy plants and 496 incineration lines lines across China. These installations boast a total waste treatment capacity exceeding 280,000 tons/day (excluding Hitachi).

In May 2021, SUS achieved a significant milestone with the operation of the first domestic 1,000-ton mechanical grate furnace at the Beijing Yanjiao Project (Sanhe Project). This groundbreaking technology not only reduces unit investment and operational cost but also delivers high combustion efficiency, high thermal stability, and a low ash thermal scorch reduction rate.

- Prev:None

- Next:High Parameter Waste Heat Boiler Technology