The third generation of automatic combustion control (ACC) technology

|

Technical Introduction

|

|

The Third Generation Automatic Combustion Control(ACC) Technology:

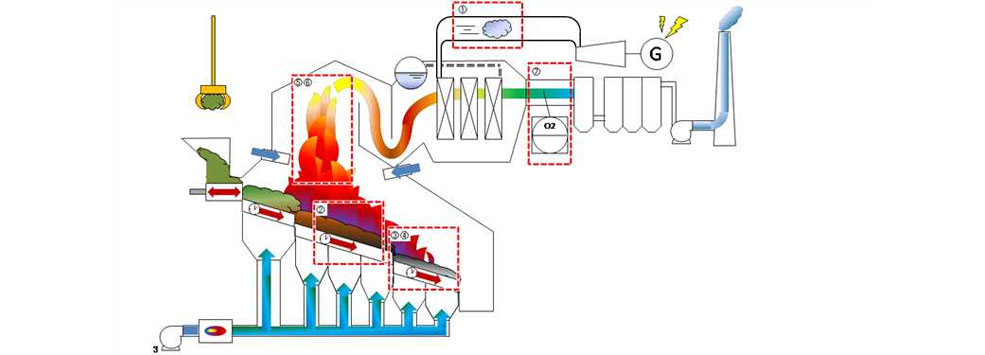

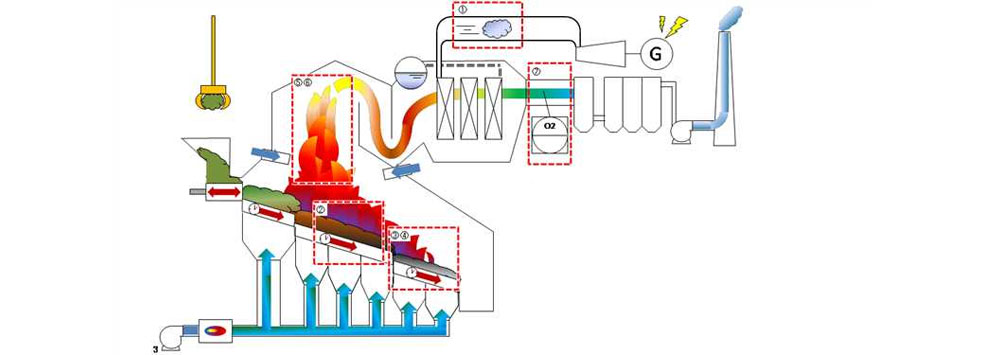

Utilizing the main steam flow of the boiler as the primary control parameter and various equipment parameters as secondary control variables, our website-based system employs process theory calculations to derive a set of standardized output values. These values undergo correction processes before initiating continuous adjustments to the actuating equipment. This iterative approach ultimately achieves automatic combustion control of the incinerator. SUS presently employs the cutting edge third generation of automatic combustion control technology. This advanced system enables combustion imaging recognition, real-time monitoring, and measurement of the flame distribution within the furnace chamber. Additionally, it facilitates precise adjustments of combustion for optimal performance.

|

Highlights

|

Main steam flow control ensures stable boiler output Promotes scientific and complete combustion of waste

|

|

Waste layer control ensures consistent waste throughput Maintains high productivity levels |

|

Waste combustion position control Enables minimization of thermal burn rate

|

|

Precise temperature control within the furnace to ensure an optimal temperature range Reduction of pollutant emissions

|

|

Regulating oxygen concentration in flue gas ensures minimum pollutant emissions Contributing to environmentally friendly and low-carbon production practices

|

|

|

Technical Applications

SUS’s ACC system is renowned for its reliability and stability, ensuring consistent combustion conditions while greatly reducing operator workload. This technology has garnered numerous invention and utility model patents and has been successfully deployed in various domestic waste-to-energy projects. Notable examples include, Gaoling project, Zhuhai, Qingdao project, and Qingdao West Coast project, all of which are currently operating well.

|

Technical Introduction

|

|

The Third Generation Automatic Combustion Control(ACC) Technology: Utilizing the main steam flow of the boiler as the primary control parameter and various equipment parameters as secondary control variables, our website-based system employs process theory calculations to derive a set of standardized output values. These values undergo correction processes before initiating continuous adjustments to the actuating equipment. This iterative approach ultimately achieves automatic combustion control of the incinerator. SUS presently employs the cutting edge third generation of automatic combustion control technology. This advanced system enables combustion imaging recognition, real-time monitoring, and measurement of the flame distribution within the furnace chamber. Additionally, it facilitates precise adjustments of combustion for optimal performance.

|

Highlights

|

Main steam flow control ensures stable boiler output Promotes scientific and complete combustion of waste

|

|

Waste layer control ensures consistent waste throughput Maintains high productivity levels

|

|

Waste combustion position control Enables minimization of thermal burn rate |

|

Precise temperature control within the furnace to ensure an optimal temperature range Reduction of pollutant emissions |

|

Regulating oxygen concentration in flue gas ensures minimum pollutant emissions Contributing to environmentally friendly and low-carbon production practices |

|

|

Technical Applications

SUS’s ACC system is renowned for its reliability and stability, ensuring consistent combustion conditions while greatly reducing operator workload. This technology has garnered numerous invention and utility model patents and has been successfully deployed in various domestic waste-to-energy projects. Notable examples include, Gaoling project, Zhuhai, Qingdao project, and Qingdao West Coast project, all of which are currently operating well.

- Prev:None

- Next:None