Complete technology for ultra-high-pressure furnace dehumidification and reheat high-efficiency waste heat utilization system

|

Technology

|

|

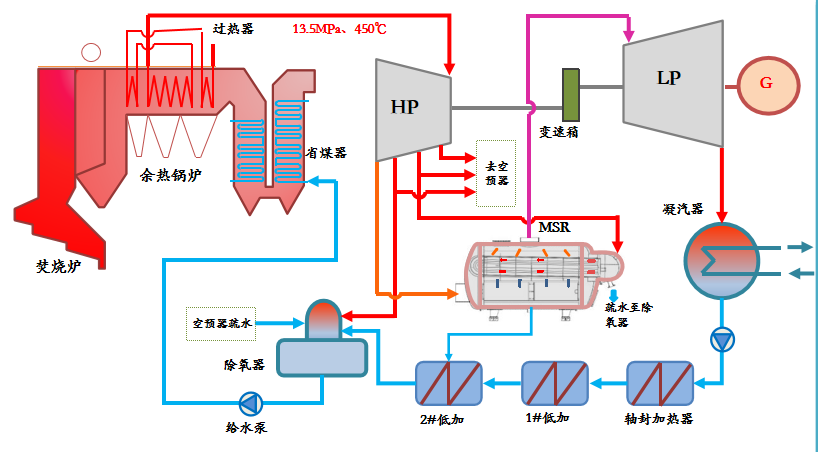

Complete set of technology for ultra-high pressure external dehumidification and reheating high-efficiency waste heat utilization system:

The dehumidification and reheating cycle system refers to a steam water cycle system in which the wet steam from the high-pressure cylinder of the steam turbine has been dehumidified and then introduced into the reheater for reheating, further increasing the steam temperature, and then returned to the low-pressure cylinder of the steam turbine to continue working. The exhaust steam from the low-pressure cylinder is discharged into the condenser, which is then reheated, deoxygenated, and pressurized before returning to the boiler. In the waste incineration power generation industry, dehumidification and reheating technologies are mainly used to break through the limitations of superheated steam temperature on pressurization to a certain extent. At present, dehumidification and reheating technologies are widely used in large thermal and nuclear power plants.

|

Technical highlights

|

High parameter Using ultra-high pressure main steam parameters

|

|

high efficiency The power generation efficiency of the entire plant reaches over 30%

|

|

Convenient control Steam turbine extraction reheating, simple system |

|

Flexible configuration Can achieve multi machine bus control operation

|

Equipment advantages

1.Drawing inspiration from the intermediate reheating process utilized in large-scale thermal power generation and the main steam reheat (MSR) manufacturing process of nuclear power technology, our solution implements a dehumidification and reheating process. This process significantly reduces humidity levels at the final stage, addressing issues related to water corrosion in turbines operating at medium-temperature and ultra-high-pressure parameters.

2. To mitigate the risk of high temperature corrosion in the reheater; we have eliminated its setup within the furnace. Additionally, we have implemented a low-temperature superheater front arrangement to ensure that the outer wall temperature of the superheater remains far from the corrosion zone. This approach makes it easier to control high temperature corrosion in waste-to-energy waste heat boilers.

3.By implementing a meticulous thermal system design and optimizing equipment configuration, we aim to achieve energy cascade utilization. This approach enables us to minimize energy resources across various stages of the system.

Technology application

The Sanhe project represents a ground-breaking milestone in the domestic waste-to-energy industry by introducing ultra-high-pressure off-furnace dehumidification and reheating technology. It stands as the first of its kind among waste-to-energy projects in China, with a plant-wide thermal efficiency exceeding 30%. Compared to medium-temperature sub-high-pressure setups, the Sanhe project demonstrates an approximate 20% increase in annual feed-in power.

|

No. |

Project Name |

Capacity(t/d) |

Main Steam Parameters(MPa,℃) |

|

1 |

Three Rivers Project |

2×1000 |

13.5,450 |

|

2 |

Xinhui Project |

2×750 |

13.5,485 |

|

3 |

Hanchuan Project |

1×1000 |

13.5,450 |

|

Technology

|

|

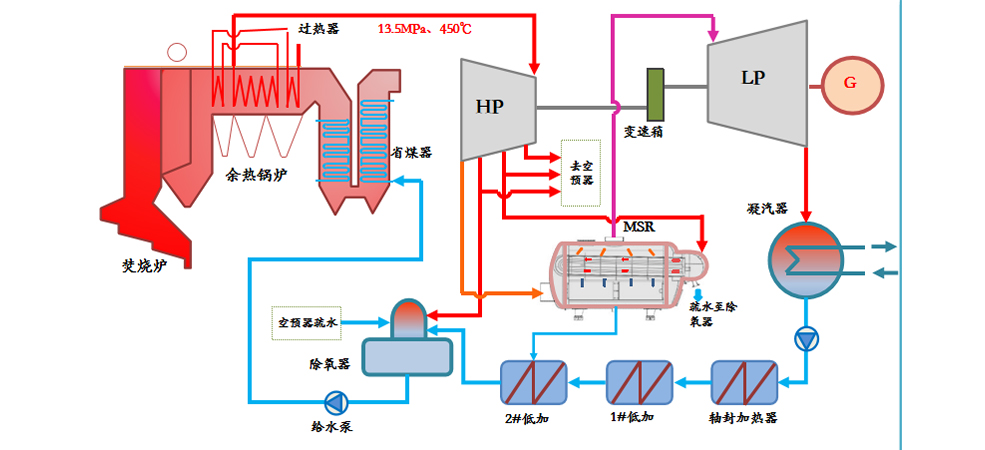

Complete set of technology for ultra-high pressure external dehumidification and reheating high-efficiency waste heat utilization system:

The dehumidification and reheating cycle system refers to a steam water cycle system in which the wet steam from the high-pressure cylinder of the steam turbine has been dehumidified and then introduced into the reheater for reheating, further increasing the steam temperature, and then returned to the low-pressure cylinder of the steam turbine to continue working. The exhaust steam from the low-pressure cylinder is discharged into the condenser, which is then reheated, deoxygenated, and pressurized before returning to the boiler. In the waste incineration power generation industry, dehumidification and reheating technologies are mainly used to break through the limitations of superheated steam temperature on pressurization to a certain extent. At present, dehumidification and reheating technologies are widely used in large thermal and nuclear power plants.

|

Technical highlights

|

High parameter Using ultra-high pressure main steam parameters

|

|

high efficiency The power generation efficiency of the entire plant reaches over 30%

|

|

Convenient control Steam turbine extraction reheating, simple system |

|

Flexible configuration Can achieve multi machine bus control operation

|

Equipment advantages

1.Drawing inspiration from the intermediate reheating process utilized in large-scale thermal power generation and the main steam reheat (MSR) manufacturing process of nuclear power technology, our solution implements a dehumidification and reheating process. This process significantly reduces humidity levels at the final stage, addressing issues related to water corrosion in turbines operating at medium-temperature and ultra-high-pressure parameters.

2. To mitigate the risk of high temperature corrosion in the reheater; we have eliminated its setup within the furnace. Additionally, we have implemented a low-temperature superheater front arrangement to ensure that the outer wall temperature of the superheater remains far from the corrosion zone. This approach makes it easier to control high temperature corrosion in waste-to-energy waste heat boilers.

3. By implementing a meticulous thermal system design and optimizing equipment configuration, we aim to achieve energy cascade utilization. This approach enables us to minimize energy resources across various stages of the system.

Technology Application

The Sanhe project represents a ground-breaking milestone in the domestic waste-to-energy industry by introducing ultra-high-pressure off-furnace dehumidification and reheating technology. It stands as the first of its kind among waste-to-energy projects in China, with a plant-wide thermal efficiency exceeding 30%. Compared to medium-temperature sub-high-pressure setups, the Sanhe project demonstrates an approximate 20% increase in annual feed-in power.

|

No. |

Project Name |

Capacity(t/d) |

MPa,℃Main Steam Parameters(MPa,℃) |

|

1 |

Three Rivers Project |

2×1000 |

13.5,450 |

|

2 |

Xinhui Project |

2×750 |

13.5,485 |

|

3 |

Hanchuan Project |

1×1000 |

13.5,450 |

- Prev:Deep Waste Heat Recovery and Supply Technology

- Next:None