Scan the QR-Code to Follow our WeChat Official

Account to Get the Latest News

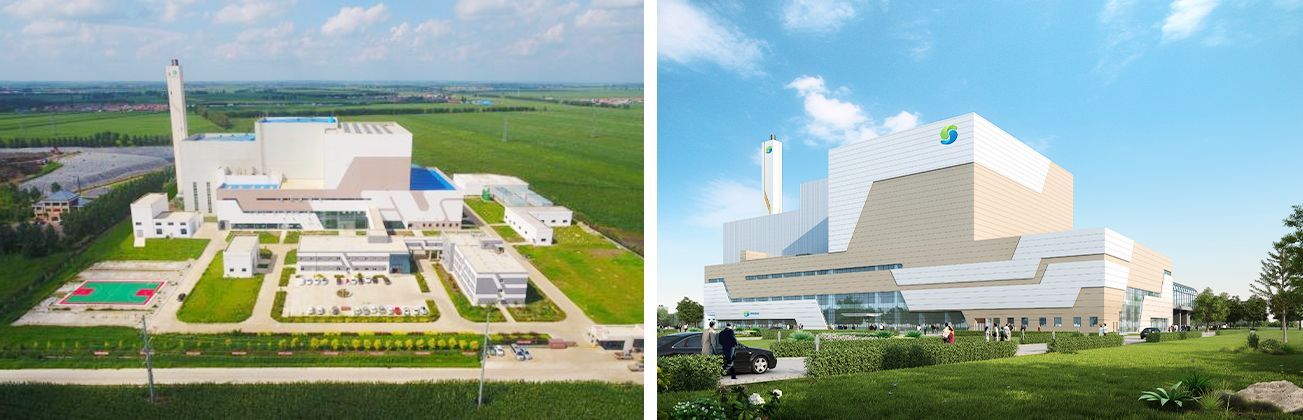

Project address:East of Landfill, Lixin Village, Chengjiao Street, Yushu City

Appointment visit contact phone number:+86 0431-83017711

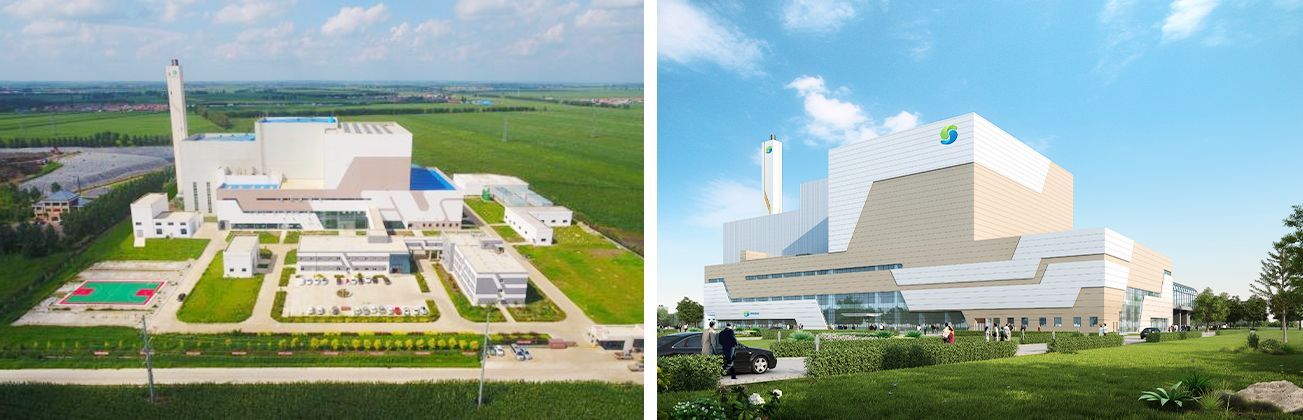

The Yushu Waste-to-Energy Project is situated on the eastern side of Lixin Village Landfill in Chengshao Street, Yushu City. This project is dedicated to achieving harmless, reduction, and resource-based treatment of household waste across Yushu City. With a robust daily processing capacity of 600 tons, the project commenced construction on October 10, 2016, and successfully commenced operation on September 29, 2018.

This project holds significance as a nationally encouraged development project, occupying an expansive area of 62,967.95 square meters. Equipped with advanced infrastructure, it includes a 600-ton mechanical grate furnace and a 12-megawatt steam turbine generator set. Additionally, the project features comprehensive systems for treating smoke, wastewater, ash, and other residues.

1. Technological Advancements

The flue gas purification system incorporates a comprehensive treatment process comprising of SNCR (Selective Non-Catalytic Reduction), semi-dry (dry) desulfurization, activated carbon absorption, and bag filter." By effectively removing harmful substances such as nitrogen oxides, sulfur dioxide, dust, dioxins, and heavy metals, the emissions of flue gas consistently adhere to national standards.

2. Robust Adaptability

The Yushu Project demonstrates remarkable adaptability operating in a cold climate characterized by low temperatures and extended winters. Utilizing the heat recovery from smoke gas, the project ingeniously reheats the filtrate to spray back into the waste bin, facilitating ice and snow removal and enhancing waste fermentation efficiency. This innovative process not only improves the calorific value of the waste entering the furnace but also serves as a case study for similar projects in the northern regions.

1. Technological Advancements

The flue gas purification system incorporates a comprehensive treatment process comprising of SNCR (Selective Non-Catalytic Reduction), semi-dry (dry) desulfurization, activated carbon absorption, and bag filter." By effectively removing harmful substances such as nitrogen oxides, sulfur dioxide, dust, dioxins, and heavy metals, the emissions of flue gas consistently adhere to national standards.

2. Robust Adaptability

The Yushu Project demonstrates remarkable adaptability operating in a cold climate characterized by low temperatures and extended winters. Utilizing the heat recovery from smoke gas, the project ingeniously reheats the filtrate to spray back into the waste bin, facilitating ice and snow removal and enhancing waste fermentation efficiency. This innovative process not only improves the calorific value of the waste entering the furnace but also serves as a case study for similar projects in the northern regions.

Scan the QR-Code to Follow our WeChat Official

Account to Get the Latest News